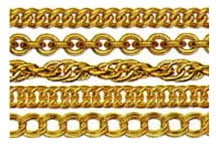

Chain Cutting Faceting Machine

Best Model Amol Chain Cutting Faceting Machine.

Specification:

- The programmable logic controlled (plc) fancy diamond faceting machine can generate decoration on various flat and rectangular chains in steps and alternative intervals .

- The machine is pneumatically operated for long term toruble free operations.

- The machine is equipped with programmable logic controller. Stored designs can be selected as desired thus giving flexibility in production and is user friendly.

- The special adjustable horizonal head gives flexibility in generating designs on narrow and wide chains ensuring distortion free machining.

- All the machine components are machined on precision cnc machines and are hardened and ground. These components are individually inspected for accuracies. The machine is assembled in a controlled environment.

Technical Data

| Dimesion | 28 inches * 24 inches * 64 inches (l*b*h) |

|---|---|

| Weight | 450 kg |

| Input power | 440 voltage three phase & neutral |

| Air supply | 6 bar or 100 psi |

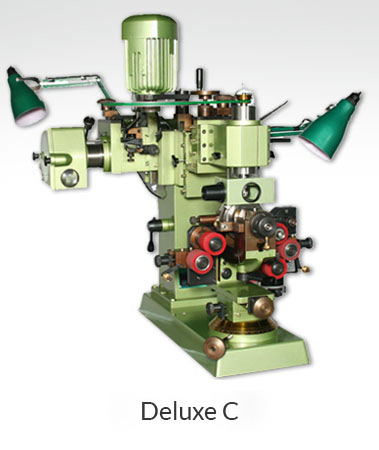

Design

Best Model Amol Deluxe Combined Head Horizontal / Vertical Chain Cutting Faceting Machine:

Other Details:

- suitable for V-Cuts, Flat Cust, Lines, Stars on flat chains

- Manual feed lever with an adjustable depth screw for depth of cut on job for Step Cut

- Micromatic screw for depth adjustment for lapping and chamfers

- Chain is pulled forward continuously by PMDC motor and controller at speeds ranging from 0-110 RPM OR manually in steps by 120 teeth divider gear mechanism.(Step Cutting)

- The machine is complete with a Sturdy Base, Indexing Unit, Ø 110 mm Revolving Clamping Discs, Vacuum Attachment For Gold Chips Recovery, Chain Winder With Bobbin (Optional), Magnifying Glass Attached To Machine, Depth Indicator Dial, Electric Panel Board, Service Spanners & Spare Belts

Specifications:

| Model | SH-H |

| Horizontal Spindle Speed | 8000-10000 RPM |

|---|---|

| Tool Holder Diameter | 120 mm |

| Puller Speed | 0-110 RPM |

| Power Supply | 1 Phase 230 V 50Hz |

Jewellery Chain Faceting Machine:

Other Details:

- Ideal for Step up (Lines, Starts, V’s, Checks) on flat chains. Surfacing & Bevelling can also be done.

- Automatic cuts can be made at a pre-defined Angle, Depth and Distance at a time.

- The machine consists of Two Z-Axis. One for cut depth adjustment and the other for automatic up-down movement of the chain.

- Moving the chain forward and Z-Axis Up-Down Motion is synchronization via cam system.

- The machine is complete with a Sturdy Base, Indexing Unit, Ø 110 Mm Revolving Clamping Discs, Vacuum Attachment For Gold Chips Recovery, Chain Winder With Bobbin (Optional), Magnifying Glass Attached To Machine, Depth Indicator Dial, Electric Panel Board, Service Spanners & Spare Belts.

Specifications:

| Model | SH-H Auto |

| Spindle Speed | 8000-10000 RPM |

|---|---|

| Tool Holder Diameter | 120 mm |

| Puller Speed | 0-110 RPM |

| Power Supply | 1 Phase 230 V 50Hz |

| Machine Weight | 260 |